GO Virginia Region 2 Resource Portal

GO VIRGINIA REGION 2 PROJECT: Industry 4.0 for the ACE Workforce

In 2021, Virginia Tech was competitively selected as one of the finalists in the Economic Development Administration’s Build Back Better Regional Challenge Competition. The Phase I award helped establish an Automated-Connected-Electrified (ACE) Coalition of over 150+ public, private, and non-profit organizations, which are the backbone of this project.

Industry 4.0 for the ACE Workforce is a cluster scale-up project funded through GO Virginia Region 2 with an overarching mission to establish Virginia's Region 2 as global leaders in next-generation transportation manufacturing and automation.

Goals of this project include:

- Improve communication through the region by leveraging and growing the existing ACE Coalition of education, industry, and economic development professionals.

- Reduce the number of unfilled in-demand positions in the transportation and autonomy sector in the region through direct technical assistance to companies, building a unique pipeline to identify and train future workers.

- Training and career pathway development through leveraging the Industry 4.0 curriculum.

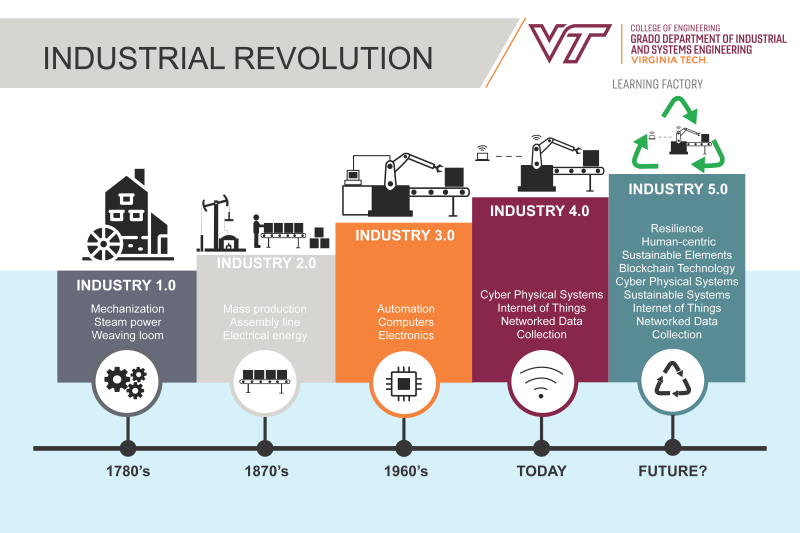

WHAT IS INDUSTRY 4.0?

TESTIMONIALS:

"The recent pandemic highlighted the need for a much stronger and resilient manufacturing capability that is less reliant on importing products, especially in critical supply chains. At the same time, manufacturers are challenged with hiring and retaining the workers required to meet their needs. The increasing demand for growth and the constraints of traditional workforce development put manufacturers in a bind. Building the agile and resilient supply chains we need for our future security depends upon the ability of manufacturers, especially small manufacturers, to adopt advanced manufacturing technologies to improve the productivity of our existing workforce while providing upskilling opportunities for sustainable growth."

Dean Young, Vice President, Business Transformation

GENEDGE Alliance

"Industry 4.0 technologies offer industries in our region the ability to achieve a higher level of efficiency simply by leveraging high-speed communication and connectivity. Manufacturing is a complex system with many moving parts and Industry 4.0 has the potential to provide instantaneous status on each and every part of the process. The information gleaned from the process and the speed at which it can be utilized stands to make tremendous strides in efficiency and productivity.

The benefits of transitioning to the more connected Industry 4.0 model in manufacturing are plentiful, however, the road to implementation is unique to each industry in our region. We feel strongly that adoption of new technologies is critical to manufacturing but are also mindful of how difficult it can be for legacy manufacturers to make the necessary changes. We at VWCC acknowledge that the path will be different for each of our stakeholders and are willing to provide the discussions and support necessary to ensure our industries successfully transition to Industry 4.0."

David Berry, Mechatronics Professor

Virginia Western Community College

"I have had the pleasure of being involved in Industry 4.0 initiatives to connect real-time data with decision makers in the manufacturing sector for over 20 years. Ultimately, these solutions have been about reducing avoidable waste and driving costs out of the supply chain. Given the recent demographic trend of baby-boomers exiting the workforce and the challenges of recruiting Millennials and GenZ into the manufacturing sector, these ‘connected solutions’ are now becoming far more valuable in terms of creating a work culture where our next generation of leaders will thrive. Wealth creation from these technologies is also opening more pathways to the middle class for a broader segment of our communities. It is an exciting time to be involved in Industry 4.0!"

Jay Foster, CEO and Founder

Flex Metrics

RECENT UPDATES:

Upcoming Events:

coming soon!