Facilities in the Aerospace Engineering Design Lab

- Flow Mach 100 waterjet

The Flow Mach 100 waterjet uses a concentrated stream of water mixed with a garnet abrasive at very high pressure. The waterjet has a cut bed of 4 feet by 8 feet and can cut materials up to 2 inches thick. It has a very clean cut that requires minimal post processing and has successfully cut materials from 1/16” aluminum to 1” thick steel. It has cleanly cut borosilicate glass from 1/8” to ½” as well as carbon fiber and fiberglass plate up to ¼”. The Flow waterjet has been a great asset to Ware Lab Baja, Formula, HEVT and Astrobotics teams and AEDL teams Wind Turbine, RockSat-X, OLVT, NASA SLVT, and Rocketry at VT.

- WAZER Water Jet (small water jet)

The WAZER water jet router (located in the AEDL machine shop) is used to cut materials that may cause excessive and hazardous dust when cut or drilled with other power tools. The water jet uses an abrasive that is mixed with high pressure water to cut through glass, plastic, aluminum, titanium, mild and hardened steel, carbon fiber and fiberglass plate. When using the Waterjet, note:

· Material size maximum for the Wazer are: 14” x 19” x .5” thickness

- X-Winder Filament Winder

The AEDL filament winder is used to apply epoxy to carbon fiber or fiberglass ribbon or tow to make or reinforce tubes by wrapping material around a mandrel to create a strong and light structural component.

- Composite rotisserie

The composite rotisserie is used to aid in layup of composite materials and epoxy resin to create or reinforce generally round structural parts. The equipment has a variable speed control to adjust the rotational speed. A basic kitchen timer is used to limit the run time and prevent it running all night.

- Omtech 100-Watt Laser cutter/engraver

The Omtech 100W laser is used to cut or engrave plywood, acrylic, leather, or rubber up to 3/8” thick. The laser can also etch glass or metal (requires pretreatment with a metal etching spray). The laser also has a rotary attachment which is useful for etching designs or text into metal cylinders.

Due to the inherent risks associated with the use of the laser cutter, only students that have been trained on the laser setup, use and clean up are allowed to operate this LASER at any time unless. AEDL students may operate the laser only after he/she has received the proper training by the AEDL manager.

Lightburn software is installed on the laptop next to the laser and is used to create cut or etch files for the laser cutter.

NEVER, EVER, EVER exceed 75% power setting!, EVER!

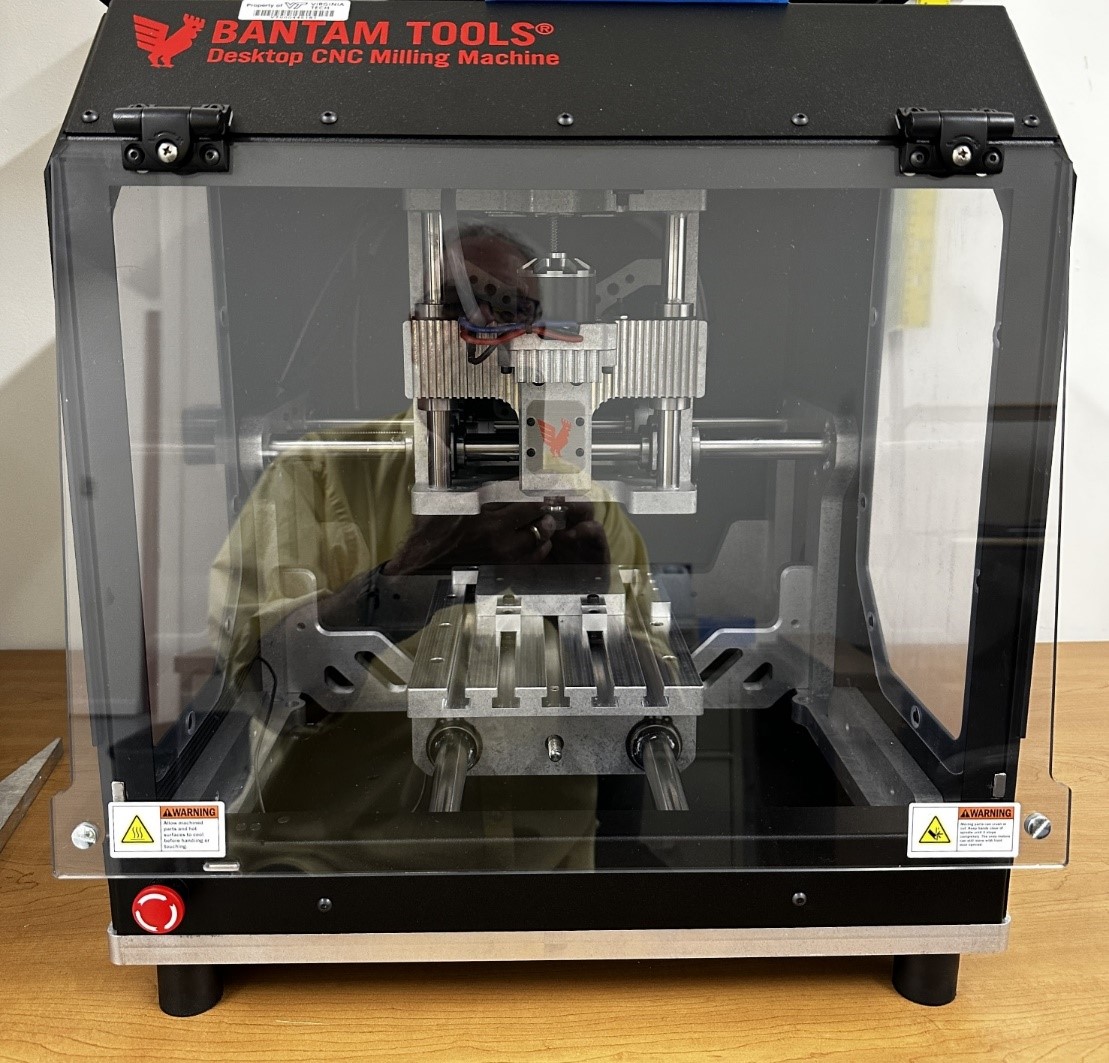

- BANTAM desktop CNC

The Bantam desktop CNC machine is only to be used for machining aluminum. Only trained operators may use his machine.

- Cricut vinyl cutter

The Cricut vinyl cutter is only to be used for cutting thin materials like vinyl and paper. It is used to create graphics and sponsorship logos for competition vehicles.

- Band Saw

The AEDL band saw is equipped with a universal blade for cutting wood, plastic, aluminum, and non-ferrous metals. DO NOT cut titanium, steel or any hardened steel with the band saw. Safety glasses are required to be worn when operating the band saw.

- Drill Press

The AEDL drill press is a multi-speed tool with a variable speed range of 540 to 2900 RPM. It also has a work light and a laser crosshair to show where the drill bit is going to place the center of the hole. Safety glasses are required to be worn when using the drill press.

- Belt/Disc Sander

The AEDL belt/disc sander is used to shape material or to remove small amounts of material from nonmetallic materials. Safety glasses are required to be worn when using the belt sander. A dust mask is required at all times when using the sander.

- Chop Saw

The chop saw is used to cut aluminum, fiberglass or other composite materials. It is used for cutting tubing, 80/20 extrusions and other aluminum bar, rod or square tubing. There are separate blades for aluminum (green label), steel (blue label), and composites (orange label). The machine does not have a dust or chip collection feature so it is very important to use the correct PPE when cutting fiberglass or carbon fiber composites.

Safety glasses are required to be worn at all times when using the chop saw.

A dust mask is required at all times when using the chop saw.

The aforementioned facilities and equipment are for use by AEDL teams only.

-

General Item

-

General Item

-

General Item

Contact the Aerospace Engineering Design Lab

501 Industrial Park Road, Blacksburg, VA 24060

bschoner56@vt.edu