A team of researchers from mining and mechanical engineering is developing a wearable exoskeleton designed to revolutionize mining safety.

In the life of a miner, physical endurance is crucial. Carrying tools, operating machinery, and moving through underground passages without being able to stand fully upright can take a toll on the people who do these jobs. Back injuries make up nearly 25 percent of all work-related injuries that lead to time off in the industry.

But what if there was a way to lift this burden — literally? Researchers in the College of Engineering are designing a solution that could transform the way miners work: a back-support exoskeleton designed specifically for them.

The team includes:

- Alan Asbeck, associate professor in the Department of Mechanical Engineering

- Nino Ripepi, associate professor in the Department of Mining and Minerals Engineering

- Bahareh Nojabaei, associate professor in the Department of Mining and Minerals Engineering

While the number of people working in coal mining has declined in the U.S. over the past 100 years, there still remain tens of thousands of people whose daily job includes pulling minerals from the earth for use in energy, technology, and industry. Some mining is done close to the surface, but in regions where the target material is located further underground, it’s still necessary to travel through subterranean tunnels to reach it.

To preserve miners’ health, the research team from Virginia Tech has pooled their expertise to create a new safety tool designed specifically for the space.

A miner problem

In the challenging environment of a mine, the most common injury is to the back. Mining has a rate of 37 back injuries per 10,000 workers each year, with underground coal mining holding the highest average at 54 injuries per 10,000.

Back injuries are particularly acute in low-seam mines, which represent more than 25 percent of coal mines. The ceiling is often no higher than 42 inches, more than a foot shorter than the average human height. Workers must continuously kneel, crouch, or stoop, which puts constant strain on their lower backs.

Preventing back injuries for industrial workers is a big part of the research portfolio of Alan Asbeck, associate professor of mechanical engineering.

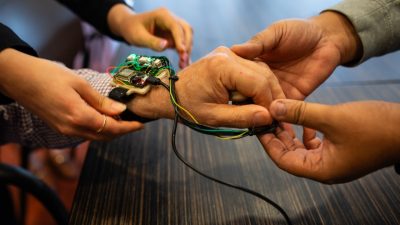

For more than a decade, Asbeck has led a team that has produced a number of wearable support suits, including a supportive brace developed with Lowe’s for their retail employees and a subsequent project to make exoskeletons for farmers. Asbeck’s exoskeletons are fitted so that they move with a user’s natural motion, twisting and bending while still providing strength.

Following success in the lab, members of Asbeck’s research team launched the company Element Exo to produce the technology commercially. Now, Element Exo is bringing that experience back as an industry partner with Virginia Tech on this new project: modifying the Element exoskeleton to save the backs and bodies of miners.

Suited for the task

The Element exoskeleton is uniquely suitable as a starting point: It is the only unpowered back-support exoskeleton that can offset more than 40 pounds from the wearer’s back — twice as much as any other exoskeleton — making it perfect for the heavy loads in mines. It is dust resistant and washable, a needed feature for dusty mine environments. In logistics and manufacturing settings, the Element has successfully decreased fatigue and the risk of back injuries among workers while increasing their productivity by as much as 20 percent.

While the wide-open spaces of a big-box home improvement store demand one kind of rig, the confines of a mine have a different roster of rigors. To create a new approach for a new industry, Asbeck’s team will be talking with miners and testing exoskeleton modifications — like integrating a standard mining tool belt — with them to ensure that the final result is just what they need.

“Having worked with a wide range of industries and individuals over the last decade, we are excited to create something that meets the needs of those in the mining labor force,” Asbeck said. “This is a great opportunity to offer technology to these workers that will target the source of many of their injuries and hopefully make them less tired and sore at the end of the day.”

The benefit of expert colleagues

Nino Ripepi and Bahareh Nojabaei, associate professors in the Department of Mining and Minerals Engineering, are bringing their expertise in mine design, operations, and health and safety to the project to ensure the exoskeleton integrates well into the mining industry.

“With a background in mechanical engineering and now working in mining engineering, I see this project as a great example of how both fields can enhance health and safety in mining,” Nojabaei said. “One area of my work involves data analysis in mining operations, ensuring exoskeleton designs are suited for the mine environment and adaptable to individual physical characteristics. By analyzing miners' survey results, we translate data into measurable design parameters, allowing us to continually improve the exoskeleton.”

As director of the Virginia Center for Coal and Energy Research, Ripepi has established strong relationships with mining industry partners, who will provide operational tours, recommendations for exoskeleton use in mines, and assistance in testing exoskeletons in real-world underground mining environments.

“The most exciting part of this research to me is to test a modified exoskeleton in a low-seam coal mine on miners and gather their feedback,” Ripepi said. “It has the potential to be a game changer in mines where you are constantly walking, working, and lifting while stooped over and putting excessive strain on your back muscles.”

The research team will also test the exoskeleton in Virginia Tech’s state-of-the-art Center for Autonomous Mining.

The center’s mock mine enables researchers to refine the exoskeleton's capabilities in a controlled yet authentic mining environment, while advanced mine simulators and VR applications put the exoskeleton to the test in a variety of scenarios.

All of this will hopefully create a commercially viable exoskeleton that will lighten the load for miners. "If we can demonstrate a significant benefit to miners' health during this project, it could pave the way for implementation across many other types of mining,” said Ripepi. “This can lead to long-term benefits for the mining industry and an increased impact for the research.”

Photos and video by Peter Means

If you want to have an impact on our students and faculty like those featured in this magazine, support the College of Engineering. For more information, call (800) 533-1144.

-

Article Item

-

Article Item

-

Article Item