Virginia Tech engineering students take the race underwater with the Human Powered Sub team, built for the International Submarine Races.

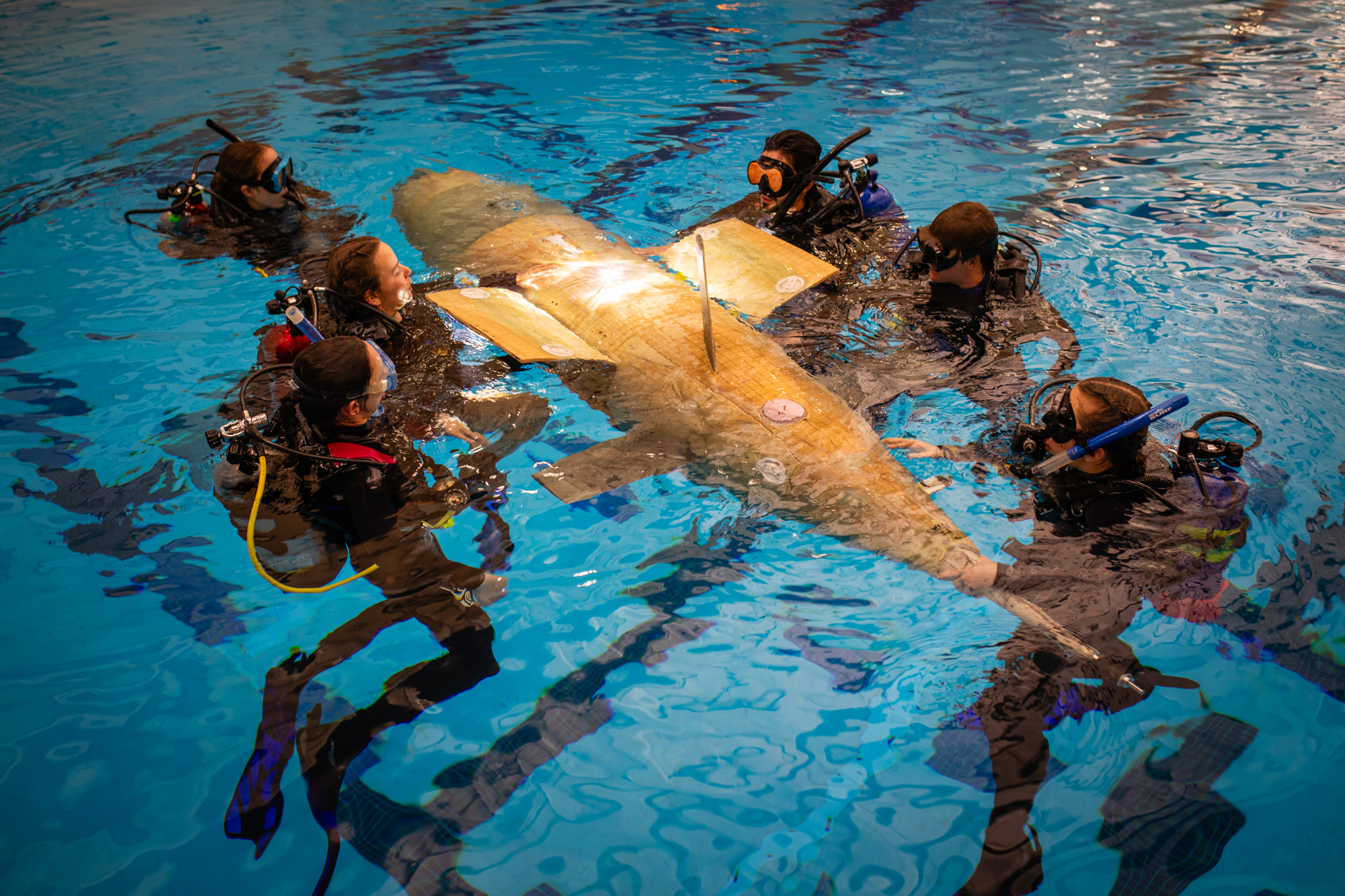

At 6:30 a.m. on a Sunday, the Human Powered Submarine team gathers in the Ware Lab to review dive safety and prep for the day’s pool practice runs at the Christiansburg Aquatic Center. Surrounded by tools, scattered parts, and hanging scuba gear, the group listens closely, each member playing a role in getting the sub water-ready. It’s a familiar scene, one that unfolds a few times a month as the team prepares for the International Submarine Races in June.

What is the Human Powered Sub team?

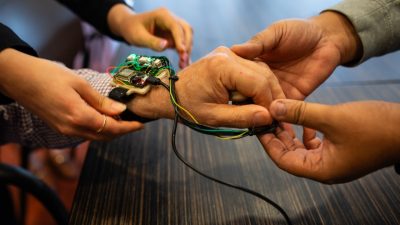

The Human Powered Submarine team at Virginia Tech, founded in 1991, is an undergraduate engineering design team focused on building a submarine that’s both piloted and powered by a human. The process starts with a design year, when the four sub-teams — electronics, hydrodynamics, controls, and structures — plan major systems, followed by a build year when those plans are brought to life.

Along the way, most of the team's 45 members — primarily students in aerospace and ocean engineering, mechanical engineering, electrical and computering engineering, biomedical engineering and mechanics, and industrial and systems engineering — earn scuba certification so they can test the sub during trials at local pools and in the flooded depths of a former Hokie Stone quarry.

The aquatic objective of this uniquely immersive engineering challenge? Racing a "wet sub" — completely flooded and piloted by a scuba-equipped teammate — at the International Submarine Races, a biennial competition where pilots compete for the fastest time over a 100-meter straight course, completing multiple runs over several days.

How the sub works

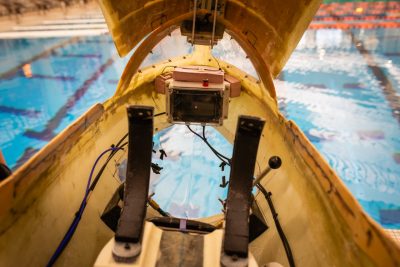

Fully flooded design

The sub uses a "fully flooded" design, meaning the interior is completely filled with water. A support diver assists the pilot on descent, sharing a secondary regulator for oxygen. Once inside the sub, the pilot switches to a smaller oxygen tank mounted within the cockpit.

Propulsion

As the name says, this sub is human-powered. The pilot clips into pedals and propels the sub just like riding a bicycle. A chain-and-gear system transfers this motion using a bevel-and-pinion gear set to turn the propeller shaft, driving the sub forward.

Steering

The sub features two steering systems. The primary is a manual setup that uses joysticks and cables to control the tail fins: Vertical fins steer left and right, while horizontal fins control ascent and descent. A second, in-development system uses sensor data for autonomous steering, allowing the sub to maintain a level, steady course without constant pilot input.

Work in the Ware Lab

The team has dedicated space in the Ware Lab in Blacksburg, where they meet regularly to collaborate and carry out all their work. There they also run flow simulations on hull designs using in-lab computers, helping to optimize the sub’s efficiency in the water.

On pool testing mornings, the team gathers in the lab to review dive safety protocols and finalize the day’s plans. It's crucial to be clear and coordinated ahead of time, as underwater communication is limited. The motto “Have a plan, dive the plan” helps keep everything running smoothly.

Practice day

Along with the occasional dip in a nearby Hokie Stone quarry, the team practices at a variety of local pools, with the choice of location often depending on how easily the sub can be brought into the facility. On this particular day, the team trained at the Christiansburg Aquatic Center in Christiansburg, Virginia — a quick trailer ride from the sub's home base at the Ware Lab.

Since most team members have never dived before, they must get scuba certified, a process that takes about two long weekends. The team works with Aquatrek Adventures, a Salem, Virginia–based dive shop that provides certification training, gear, and air. Chuck Swecker, the shop’s owner, is a constant presence at pool tests and supports the team in countless ways.

The competition

The team's final design will be put to the test at the International Submarine Race, held June 22–27 at the Naval Surface Warfare Center in Carderock, Maryland. Sponsored by the Foundation for Underwater Research and Education, the races were created to turn the tide of a projected shortfall of ocean and marine engineers. Now teams from high schools and universities across the world bring their subs together to compete on measures of speed, efficiency, design, use of technology, innovation, even team spirit.

Win or lose, the students behind Virginia Tech's Human Powered Sub Team cherish their deep dive into a project that tests both technical expertise and underwater survival skills — even at 6:30 on a Sunday morning.

Meet the team leads

Cara Johnston

President

Mechanical Engineering, ’25

"I love being able to combine a love of scuba diving with hands-on engineering work. This team has allowed me to become much more confident in both diving and engineering, and this experience has truly been the highlight of my college experience."

Ben Keenan

Head of Design

Mechanical Engineering, ’25

"Working with engineers of multiple different disciplines helps broadens my knowledge of engineering."

Maggie Campbell

Hydrodynamics Lead Engineer

Ocean Engineering, ’26

"I have learned so many valuable lessons from this team, both about working with others and about engineering, that I would not be able to get anywhere else. I love every minute I spend with my teammates, who have become some of my best friends."

Niranjan Aradhey

Electronics Lead Engineer

Mechanical Engineering, ’27

"What I love about this team is the uniqueness of the design challenge. Building a sub that operates 20 feet underwater exposes us to various challenges that I wouldn't really encounter elsewhere. I also really enjoy our team's culture. Having made some really good friends through the team, I think we strike a good balance between having lots of fun and getting work done."

Charlie Giglio

Structures Lead Engineer

Materials Science and Engineering, ’26

"The camaraderie of this team is unmatched. We eat, sleep, and breathe the work we put into this submarine, and I am so proud to be a part of it."

Karim Lahrim

Controls Lead Engineer

Mechanical Engineering, ’25

"I like the fact that we start from nothing and design and manufacture all the components from scratch to build a complete and working submarine."

If you want to have an impact on our students and faculty like those featured in this magazine, go here to support the College of Engineering. For more information, call (540) 231-3628.

-

Article Item

-

Article Item

-

Article Item