Blast testing this summer at the Shock Tube Research Laboratory brought together Virginia Tech and TU Dresden researchers in an innovative approach to improve infrastructure resilience.

Concrete is the most widely used construction material in the world because of its strength, versatility, cost-effectiveness, and ability to withstand a variety of environmental conditions. It’s used to create sprawling infrastructure, ultra-tall buildings, and resilient roadways.

But because concrete is brittle, these structures can still be vulnerable to high dynamic forces caused by collisions, rock falls, projectile impacts, and explosions. Such issues, unfortunately, have been gaining attention around the world, particularly in Ukraine and Israel, as human-made and natural disasters expose the fragility of concrete structures bearing extreme loads.

Eric Jacques, an assistant professor of civil and environmental engineering at Virginia Tech, has teamed up with Viktor Mechtcherine from the Institute of Construction Materials at Dresden University of Technology (TU Dresden) in Germany, to find proactive solutions that mitigate the catastrophic human and economic losses resulting from these vulnerabilities.

Making strong connections

Jacques, who directs the Shock Tube Laboratory at Virginia Tech, is no stranger to assessing the resilience of structures to blast and impact loads.

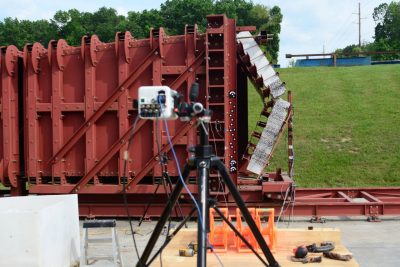

The facility, located at the Thomas M. Murray Structures Laboratory in Blacksburg, VA, boasts a large-scale gas-detonation blast simulator that uses the explosive power of an oxy-fuel mixture to mimic the intense blast waves produced during accidental explosions and terror attacks. With cutting-edge high-speed data acquisition and camera systems, Jacques’ team can analyze in detail how structures respond to these blasts.

The video on the left shows the shock tube testing a conventionally constructed reinforced concrete beam without strengthening layers. The video on the right shows a similar beam with novel cementitious strengthening layers that improved blast performance. Videos courtesy of Eric Jacques.

Mechtcherine’s team is developing mineral based-cementitious composites containing a hybrid fiber reinforcing scheme consisting of continuous textile layers and short, randomly distributed micro-fibers.

“The novel protective layers lead to tremendous benefits in preserving structural integrity and human safety,” said Mechtcherine. “Short fibers provide an outstanding damage tolerance to an otherwise brittle mineral matrix, while optimizing the efficiency of textile reinforcements and preventing spalling. In addition, our composites exhibit high thermal stability and fire resistance.”

Their work is funded by the German Research Association Deutsche Forschungsgemeinschaft (DFG).

The partnership between Virginia Tech and TU Dresden has grown over time, fueled by the belief that Mechtcherine’s innovative mineral-bonded strengthening layers could significantly boost the blast resilience of reinforced concrete — a capability uniquely demonstrated by Jacques’ state-of-the-art shock tube.

One unique feature of this reinforced concrete is the self-centering capability. After enduring a blast, the structure is engineered to revert to its original position, which minimizes damage, curtails repair costs, and reduces downtime in the aftermath of a catastrophic event.

Putting theories to the test

This summer, five concrete beams — strengthened with various mineral-bonded composite layers — underwent explosive blast testing using the shock tube. Although each test was over in just a few milliseconds, the research represented over a year of detailed planning and teamwork between Virginia Tech’s Chris Jackson and TU Dresden’s Franz Bracklow and Cesare Signorini.

For three weeks, the trio mounted beams, set up instruments, and documented damage from the blasts. And they weren't alone in their endeavor. In Germany, two experts aided with troubleshooting and digital image correlation analysis. Their international collaboration was marked by daily online meetings, where the Virginia Tech team, visiting researchers, and German colleagues discussed results and strategized future tests.

The real action, however, lay in the tests themselves. Each beam, under the watchful eyes of high-speed cameras, was subjected to progressively increasing blast loads. The aim was to determine what blast magnitude each beam could withstand before the strengthening layer reached its breaking point.

The experiments showcased how the beam’s strengthening layers can activate self-centering, which allows the beam to return to a position close to its original state after a blast that would have otherwise destroyed an unprotected member.

“The cementitious strain-hardening layer dissipates blast energy through microcracking and fracturing of fiber-matrix bonds,” said Jacques. “Meanwhile, the carbon textile reinforcement behaves like a rubber band, stretching with the beam as it deforms under the blast pressure.”

When the blast subsides, the stored energy in this “rubber band” acts as a restoring force, countering the damage from the blast and returning the beam to its original position.

Helping communities bounce back

The international team's work could redefine how we approach the security and resilience of structures against extreme loads. The Virginia Tech-TU Dresden collaboration isn’t just about fortifying buildings; it's about developing infrastructure resilience that minimizes damage, decreases repair costs, and ensures quicker recovery after catastrophic events. The discoveries made during those summer weeks at Virginia Tech could pave the way for the next generation of blast-resilient infrastructure.

"Building resilient infrastructure isn't just about reinforcing with extra concrete and steel; it encompasses the structure's capability to withstand and recover from the impacts of extreme events and natural disasters,” said Jacques. “The ultimate goal is to safeguard people, communities, and businesses."

If you want to have an impact on our students and faculty like those featured in this magazine, go here to support the College of Engineering. For more information, call (540) 231-3628.

-

Article Item