Editor's note: This story was first published in February of 2020, prior to school closures.

When the bell rang at 10:10 a.m., the kids left the classroom and Kristin Carter was alone for a few minutes to reset. She collected 16 soil test chambers from the desks in a plastic bin and carried them into a nearby supply hall. In the narrow hall, Carter pivoted past a bulletin board she’d pinned with baby pictures, a student’s drawing of Carter’s donkey Pearl on a sunlit hill, and two clips from the Smyth County News and Messenger: a photo of her son Dalton pushing off the mound before pitching a perfect game for Northwood High School in 2015 and a 2018 story about her parents selling their dairy herd.

“The Lamies’ farm, Walker Mountain Dairy Farm, is the last dairy farm in Rich Valley,” it read. At a big sink, Carter rinsed the test chambers out for her second-period life science students to use next. Then she walked out to greet them.

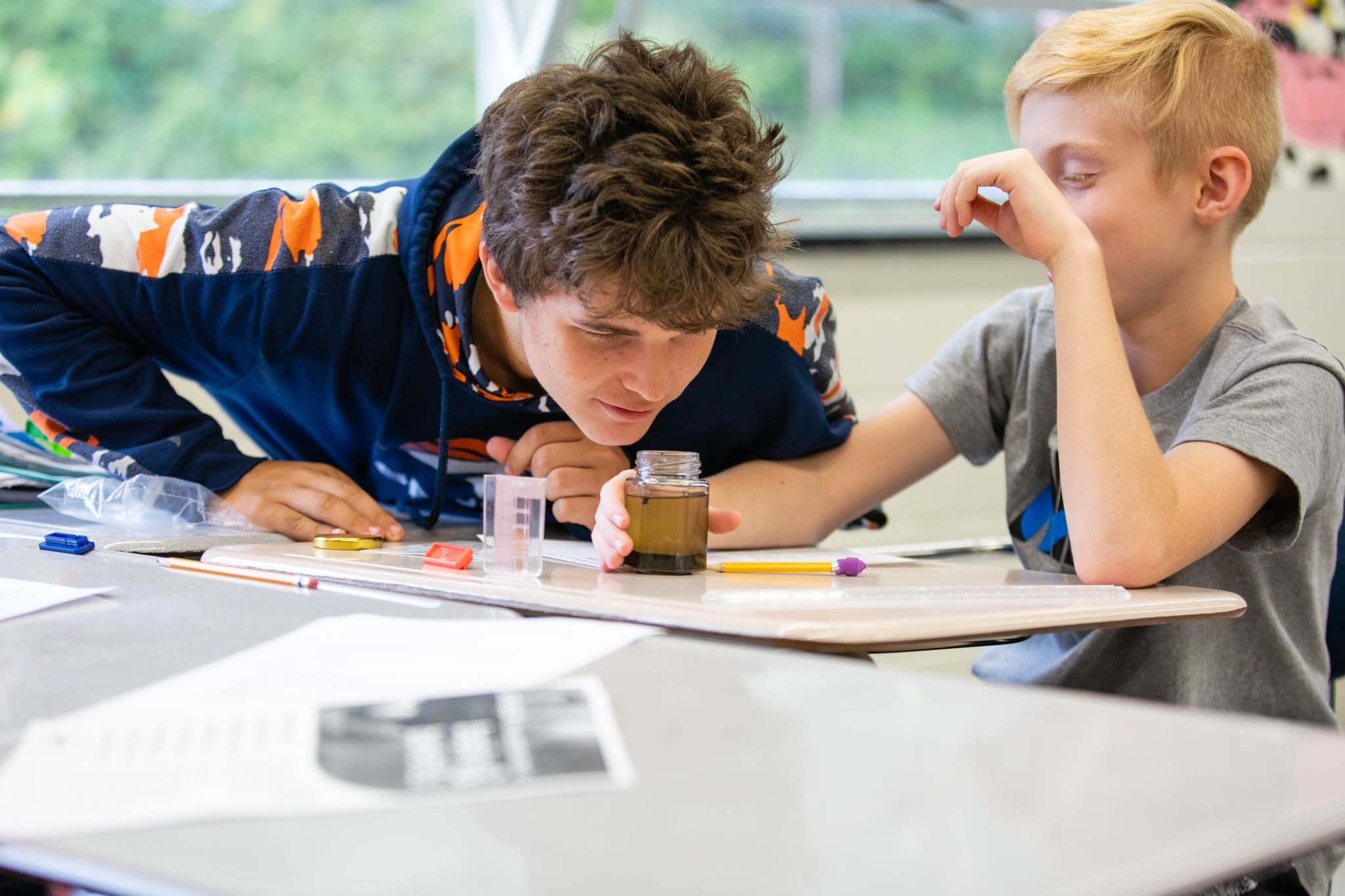

“Unscrew the lid from the jar,” Carter told the seventh-graders after they received gold-lidded glass jars filled with soil samples – black mixtures of clay, sand, and silt topped with water and a teaspoon of borax. “I’m gonna warn you, they’ve got a good stink.”

A few kids stuck their noses too close to the brims of the jars and snapped back at the smell. Carter reminded them to follow scientific precautions and waft, so they parted their fingers and gently waved the stink upward. “Mrs. Carter, this smells like farts!” one kid cried out.

They skimmed water from the samples with pipettes, filled the test chambers, and added color-changing chemical agents. “Close the chambers and shake,” Carter said. “Shake, shake, shake!”

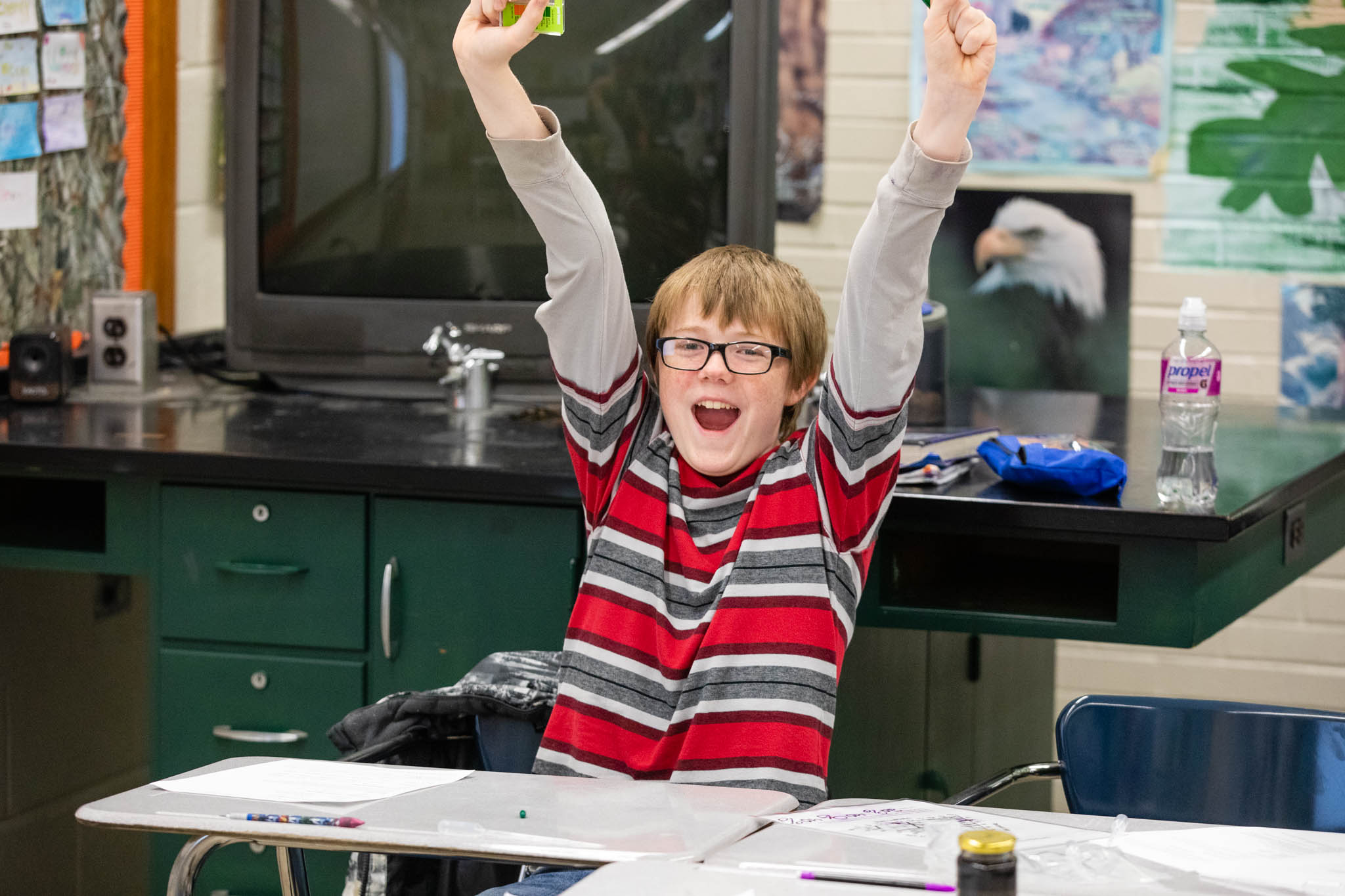

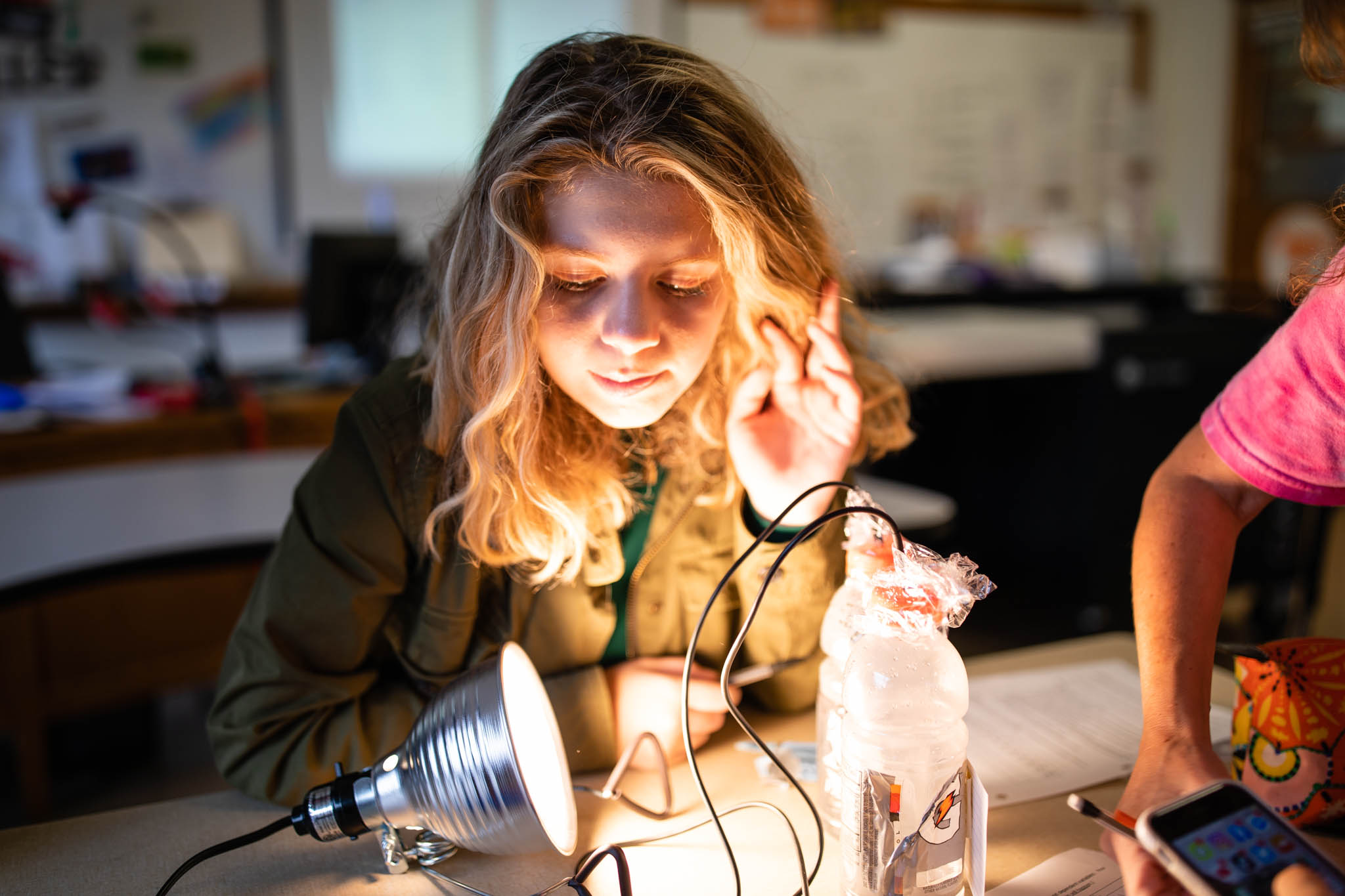

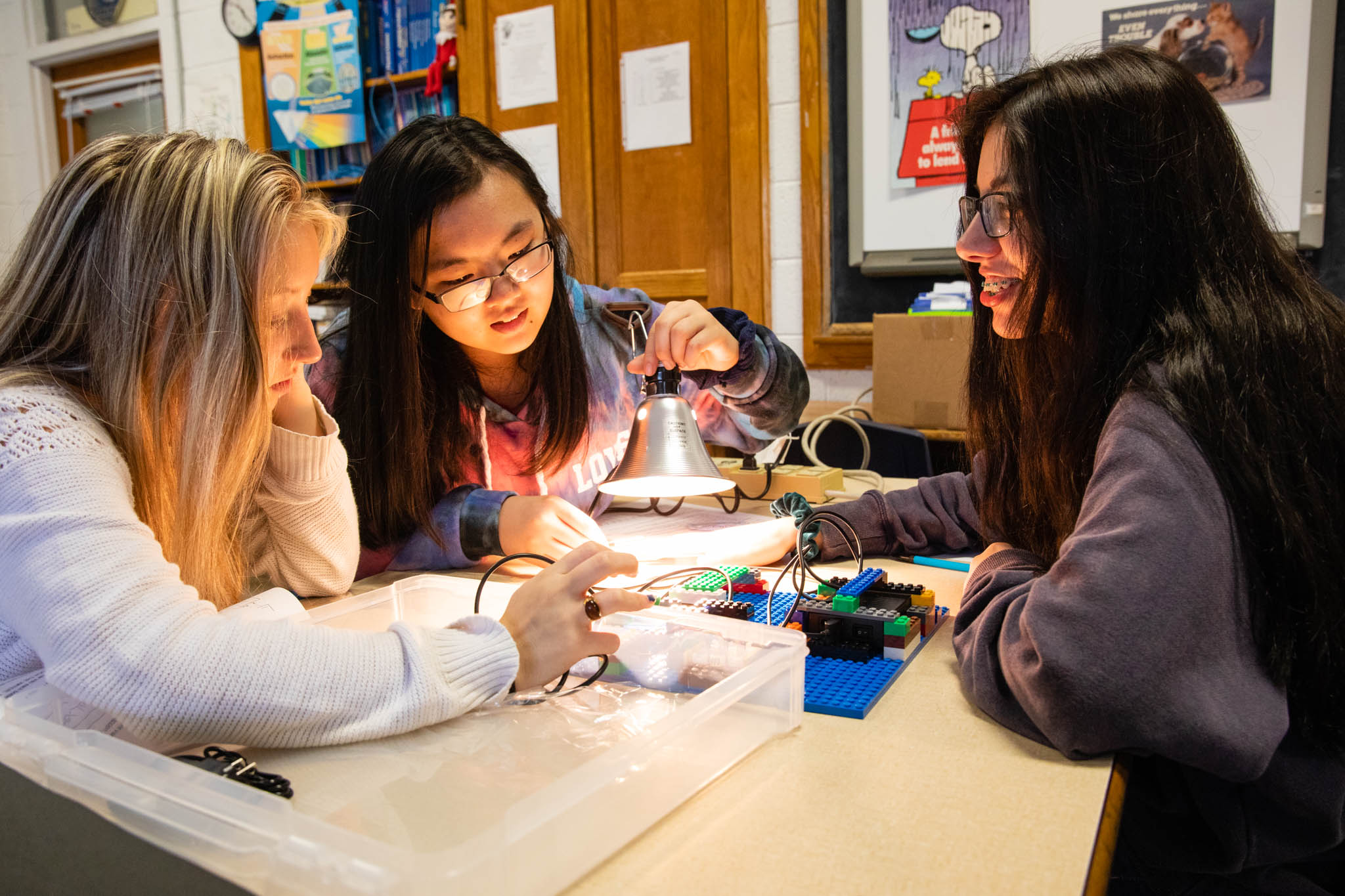

The group’s soil testing ate up the full class period, so the second half of the activity came the next day. Working from their soil data, Carter’s students looked at the genetics of corn and chose alleles to replace for traits that suited the soil. These steps gave the kids an SOL-inspired sense of genetic engineering and its use in agriculture, and to complete them, the students navigated engineering design criteria and constraints. Behind the activity is that broader goal: Carter wants kids to step into the shoes of engineers and see that it’s possible to wear them.

“You want to figure out a way to make engineering a positive experience for them,” said Carter. “They can come in, have fun with it, and see that they can do these things. It sticks with them.”

Since 2018, Carter, a seventh-grade life science teacher at Northwood Middle School in Saltville, Virginia, has worked with Partnering with Educators and Engineers in Rural Schools, or VT PEERS. The applied research program brings middle-school teachers, local industry partners, and researchers from the College of Engineering Department of Engineering Education together in the classrooms of rural Appalachia to design, run, and study hands-on engineering activities. The program is in its third and final year of funding from a $1.3 million National Science Foundation grant through the foundation’s Innovative Technology Experiences for Students and Teachers initiative.

Engaging more than 1,800 students in seven schools in the Southwest Virginia counties of Smyth, Bedford, and Giles since 2017, VT PEERS aims to open kids’ conceptions of engineering before they move on to high school and narrow down their options for higher education and careers. The program works to show students that engineering is everywhere – in roads they travel and water that flows through town – and the people behind it can be creative and curious, make mistakes and compromises to solve problems, and live in their communities.

“Those are conceptions that open doors and keep doors open,” said Jacob Grohs, an assistant professor in the Department of Engineering Education and the project’s principal investigator.

Grohs said the onus to create positive engineering experiences for students has remained on teachers thus far, despite the unique expertise and resources that university and industry partners could offer. These groups – teachers and their school systems, universities, and companies – are all positioned at important points on a child’s path to college and careers. Collaboration between them could create supportive infrastructure for teachers.

“Groups that could be talking to each other and supporting each other, aren’t,” said Grohs. “How do we find ways to get people to work together? How do we study how that process happens? Because we know that putting all of this additional work on the backs of teachers is just not tenable. We need to think about how to do it differently – how to be more broadly engaged in the education of youth in our communities.”

Looking up to local engineers

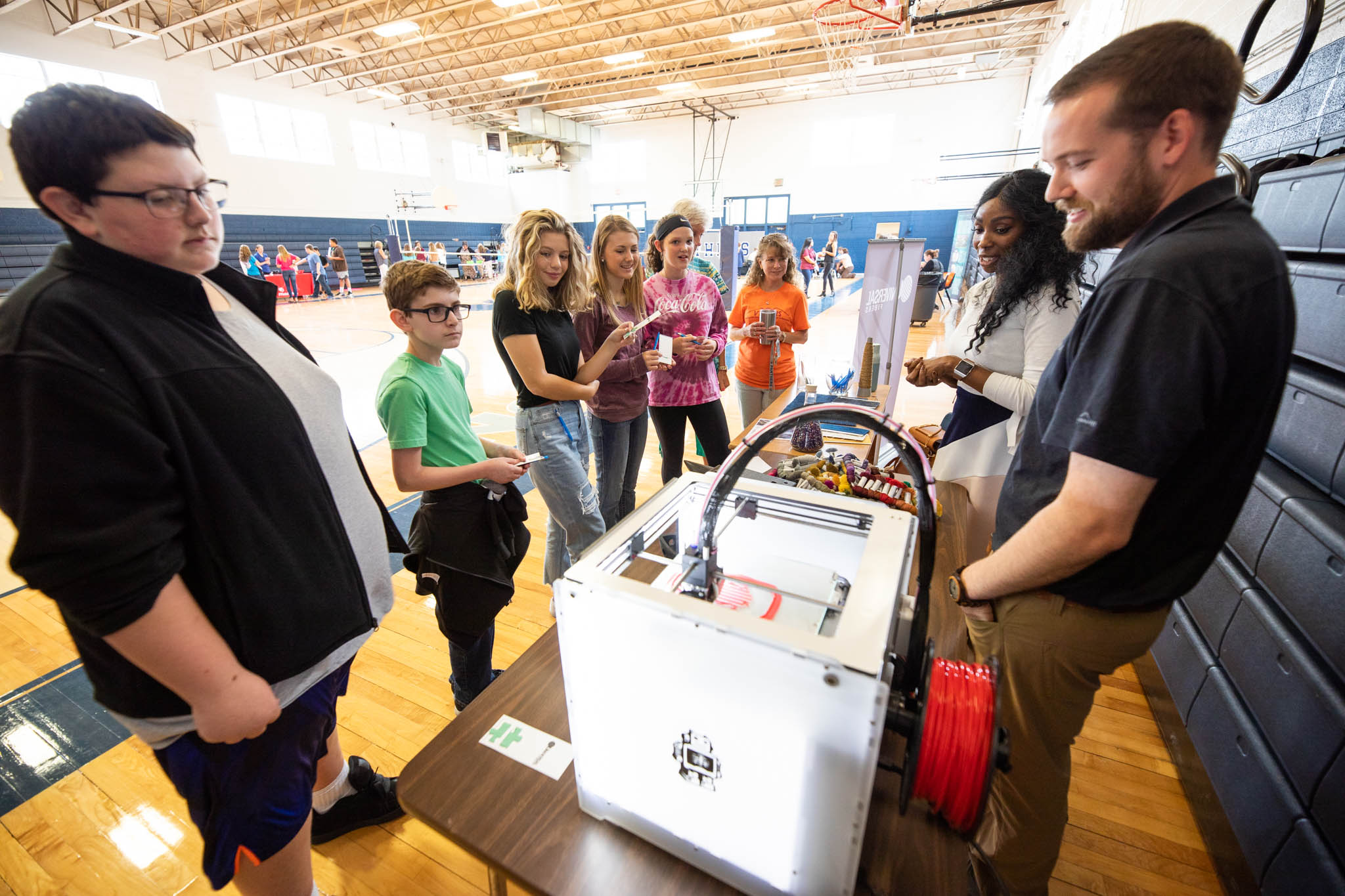

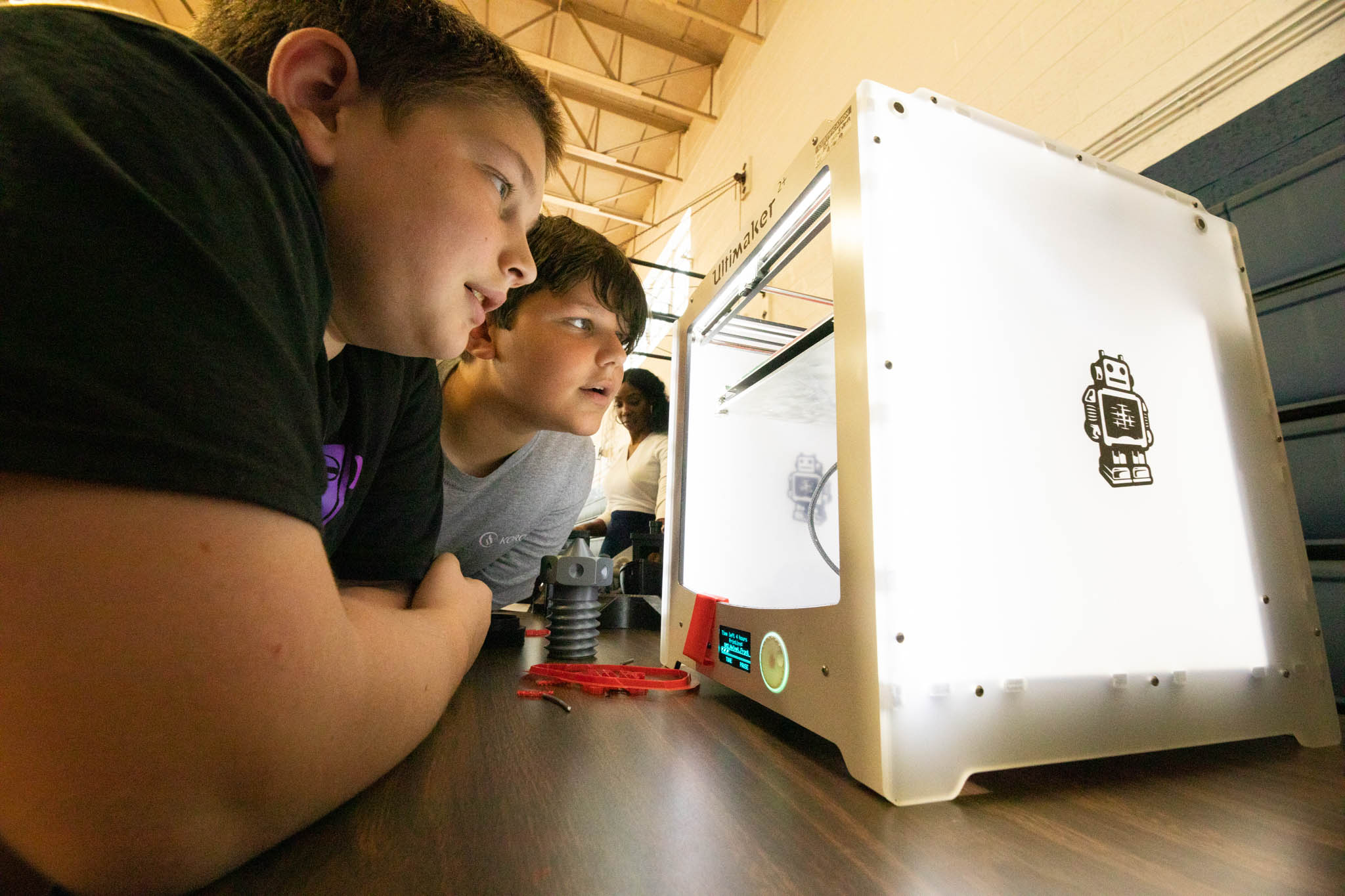

In fall, Carter and other Smyth County teachers run an activity with program partners called “Balls of Energy.” Students drop bouncy balls from different heights onto foam, wood, and carpet to test each material’s damping qualities – its ability to dissipate energy, draining the bounce from the ball. If you picked up the carpet squares for a closer look, you’d find them to be 18 inches by 18 inches with tight, thin pile, each square produced in a plant one county over. That plant belongs to a company unknown to Carter and her students until 2018: Universal Fibers.

The Bristol-based program partner sends its engineers to Smyth County schools to help instruct in-classroom activities. They float around the room, field questions, bring extra resources like carpet squares, and describe how concepts the kids learn – like damping – apply to their jobs.

“As much as anything, it’s about getting them exposed to engineers,” said Logan Pensinger, a Universal Fibers engineer and VT PEERS volunteer for Smyth County. “When I was a kid and was asked, ‘What do you want to be when you grow up?' I thought about the stuff I saw on a daily basis. Okay, I want to be a doctor. A firefighter. The stuff that engineers do behind the scenes – people aren’t necessarily aware of it. Especially at that age.”

That’s particularly the case for manufacturing, said Pensinger’s colleague and fellow volunteer, Ranae Anderson. “With this program, kids are able to see the other side of manufacturing, that it’s not what your grandparents’ manufacturing used to look like,” she said.

Pensinger is from Bristol, Virginia, but he didn’t discover Universal Fibers until after he left to study chemical engineering at Virginia Tech in 2009. While working on his senior design project, he called the company for its expertise on plastic recycling. The manager who picked up later offered him a job. But that first encounter took place only after Pensinger stumbled upon the company in a quick online search, long after he’d chosen to study engineering. VT PEERS helps Universal Fibers remove chance from its connections to potential talent and make links earlier. Industry partners Fostek and Celanese aim for the same in Bedford and Giles counties.

“The kids are able to see: here’s a job in my own area that I can be involved with, and I can make a good living, have flexible hours, and be able to stay,” said Anderson.

Curriculum designed for and by teachers

Carter’s October genetic engineering activity was one of the first in which she took the lead. The previous year, program staff would run activity instruction, while Carter observed, managed the classroom, and jumped in as she wanted. Grohs said the goal is to put her in the driver’s seat this year. When she took point, Carter ran the activity at a tight and fluid pace, as if she’d always had the role. And she wove in context.

She told her students about the importance of soil samples to farmers. Carter talked about life on her own farm, a 100-acre property that she and her husband, Michael, bought last year. It’s about a mile from school and perched on a hill with a view that stretches out to town. There, the Carters grow alfalfa and orchard grass for hay to feed the animals they raise. Carter told her students about the farm’s recent switch back to growing grasses after a brief stint with pumpkins. Her family needed their soil tested to learn how it had changed. Her students were bobbing up and down as pumpkins and grass to illustrate the transition when the bell rang.

The VT PEERS curriculum is designed to work in a culturally relevant context like Carter’s. It’s this context that fosters sustained interest in engineering, said Holly Matusovich, an associate professor in the Department of Engineering Education and a member of the research team.

“Engineering is so many things, it’s hard to pin down,” she said. “We need to talk about it in meaningful ways that make sense to the people who are living and working in a community.”

Before the school year starts, teachers and partners attend a summit held by VT PEERS at Virginia Tech. They use that time to guide curriculum design with input on Virginia Standards of Learning subjects they hope to cover – each activity must tie into an SOL, a critical planning metric for teachers – as well as subject matter with which they and their students can identify.

Activities like “Mountain Roads” have since become part of the curriculum. The engineering design challenge has students construct a road around a mountain within a given set of constraints. As kids create open-ended solutions and problem-solve like engineers, teachers can relate the roads to the winding Appalachian curves that their students may navigate going to and from school.

The Virginia Tech team is studying these activities and the collaboration itself, looking for ways to improve them, and with additional funding, expand upon them. Early in 2020, Grohs also received a CAREER award from the National Science Foundation to build out support for and study the trajectories of middle schoolers that have engaged with VT PEERS, as they enter high school in Giles and Smyth counties. Grohs will work with educators outside the science domain, like librarians and technology teachers, to enable students to continue exploring their interest in engineering.

“Virginia Tech should be a recurrent resource, collaborator, and encourager of youth, teachers, and school systems in these regions,” said Grohs.

Ranae Anderson wants the same for Universal Fibers in Smyth County schools.

“We’ve been in their backyard for 50 years, but they didn’t know we were here. We didn’t know we had anything to offer them. Being a partner in the program has helped change that.”

This material is based upon work supported by the National Science Foundation under Grant No. 1657263. Any opinions, findings, and conclusions or recommendations expressed in this material are those of the author(s) and do not necessarily reflect the views of the National Science Foundation.

Photos by Peter Means, Video by Spencer Roberts

If you want to have an impact on our students and faculty like those featured in this magazine, go here to support the College of Engineering. For more information, call (540) 231-3628.