Virginia Tech students are racing toward a more sustainable future with Sun Gobbler, an innovative solar-powered car.

While electric vehicles have been mainstream for many years, they come with one significant drawback: the need for recharging. What if a car powered entirely by the sun could recharge its battery while driving or when simply parked—it could be a game changer, offering virtually unlimited mileage on sunny days.

There are vehicles on the market today with solar panels mounted on their sun-facing surfaces, but these panels can only harness enough energy to supplement electric and hybrid vehicles, increasing their range. Current solar technology simply doesn’t provide enough energy on its own to meet the speed and acceleration demands of modern consumer vehicles.

Enter the SolarCar at Virginia Tech team. They are tackling these limitations head-on.

The primary mission of SolarCar is to build a vehicle that operates entirely on solar energy. They compete in multi-day endurance events, striving to drive as far as possible within a set time limit. The team participates in the American Solar Challenge, an organization that hosts two types of races: a three-day track race focused on completing as many laps as possible, and a long-distance endurance race spanning eight days and covering approximately 1,500 to 2,000 miles. The SolarCar team's challenge centers around endurance and efficiency, with the ultimate objective of making fully solar-powered vvehicles the future of transportation.

Promising race results

This past summer, SolarCar at Virginia Tech competed in their first-ever competition, placing 12th out of 24 teams in the single-occupant vehicle class at the Formula Sun Grand Prix in Kentucky. This achievement was particularly sweet, as they competed against and outperformed several veteran teams.

Meet Sun Gobbler

SolarCar's current vehicle, "Sun Gobbler," began development in 2021 and has benefited from the collective efforts of roughly 150 Virginia Tech engineering students. With its impressive showing in the 2024 Formula Sun Grand Prix, the team continues to test and refine Sun Gobbler's performance, looking forward to a strong showing in the 2025 competition.

With a top speed of 35 miles per hour, Sun Gobbler's average cruising speed during competitions is around 10 to 15 miles per hour. Maintaining a higher speed isn't currently feasible, as it drains the battery faster than the solar panels can replenish it. Top teams with more experience and advanced technology can sustain cruising speeds of around 30 miles per hour. SolarCar is working to increase the Sun Gobbler's cruising speed so that they can complete more laps at the 2025 race.

The team working in their lab

How Sun Gobbler works

Team SolarCar’s current vehicle operates much like an electric car, but solar panels on the hood and roof replace a charging cable. The sun energizes the solar panels mounted on the car, which provide 100 percent of the energy the car needs to function. The power generated by the solar panels is transferred to a battery pack, storing the energy for situations like climbing hills or cloudy weather when direct solar power isn’t available. From the battery pack, energy flows into the direct-drive hub motor located in the right rear wheel. This motor runs when the driver pushes the gas pedal, powering the car along the road.

Managing energy during endurance competitions

While driving the Sun Gobbler during competitions, the team must balance pulling energy from the sun and expending energy to drive the car. During morning and evening, when the sun is less intense, the motor uses more energy than the panels can produce, draining the battery. During the middle of the day, the solar intensity is high enough that the battery can fill up again. The team must continuously monitor this balance to ensure they don’t drain the battery pack too quickly and risk running out of energy.

Cooling and controlling

The cooling system ensures the batteries remain below 140°F, keeping them within their optimal operating temperature. Two fans mounted in the rear of the battery box pull air from the front of the car and circulate it in and around the battery box. The hot exhaust air is then channeled through two flexible foil ducts, safely directing it away from the driver and out the rear of the vehicle.

A low-voltage panel features an Arduino responsible for the car's ignition sequence, along with a Raspberry Pi that manages all data collected from the vehicle. The Raspberry Pi also handles the low voltage peripherals, like the lights, turn signals, and horn.

The driver operates the car using a switch panel mounted on their left, allowing control over both the high-voltage and low-voltage systems. The motor controller, temporarily housed in the plywood box shown below, converts the 110-volt DC from the battery into three-phase AC to power the motor. The motor controller is responsible for interpreting the signal from the gas pedal and controlling the motor's speed.

The car's suspension consists of a custom double-wishbone system in both the front and rear, improving driver comfort while reducing energy loss through the road.

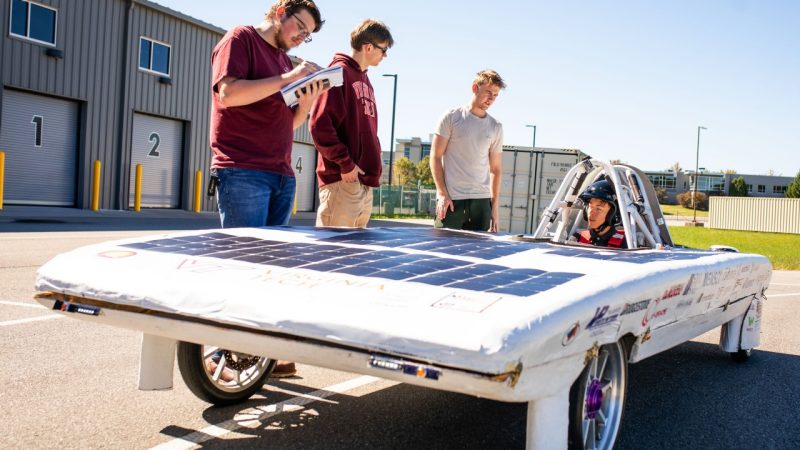

Taking Sun Gobbler to the test track

The SolarCar team's primary lab space is located at the Virginia Tech Corporate Research Center (VT CRC), and testing takes place at the Virginia Tech Transportation Institute (VTTI). Each time the team goes to the test track, the car is carefully loaded from the lab into a trailer, where it is securely strapped down for the trip. This year, the team aims to maximize testing and push Sun Gobbler to its limits, using the data they gather to help enhance its performance for the upcoming competition next July.

Testing at VTTI

On this test day during the fall semester, the team first focused on measuring the average current draw of the car at various driving speeds. This data will help determine optimal speeds for different sections of the competition tracks in order to maximize the vehicle’s range. The second test involved adding sandbags to simulate a heavier vehicle. The data collected during this test will help inform decisions about the benefits of potential weight reduction strategies for both the Sun Gobbler and future vehicle generations.

Meet the SolarCar team leads

The team leads play a vital role in project management, coordinating tasks, and setting timelines for the club. They provide technical guidance, troubleshoot issues, and mentor new team members.

Nick Whitney

Project Lead

Mechanical Engineering, ’25

"My favorite thing about the team is the culture and all the people we have. Everyone brings different perspectives, and I love working with each person individually to maximize the team's potential."

Elori Smile

Electrical Lead

Electrical Engineering, ’25

"I really enjoy the room for creativity I have in coming up with new electrical designs for the car, as well as inspiring new freshmen students to be passionate about electrical engineering."

Jake Littlefield

Operations Lead

Environmental Economics, ’24

"My favorite thing about working on the team is having the opportunity to work with such a talented and diverse group of individuals. Being able to learn about engineering as a non-engineering major is a huge bonus, and I get to learn something new every day."

Ryan Rigatti

Mechanical Lead

Mechanical Engineering and Industrial and Systems Engineering, ’25

"The reason I like being part of SolarCar is because I get to do complex design and manufacturing processes with a creative and innovative team."

Agilan Anand

Mechanical Lead

Industrial and Systems Engineering, ’26

"My favorite thing about this team is how it feels like a tight-knit family. Everyone knows everyone. There's a lot of collaboration. It's just really fun and it doesn't really feel like work; it just feels like I'm hanging out with friends who all have the same goal.

Mason Werner

Operations Lead

Industrial and Systems Engineering, ’25

“I'm thrilled to be part of a group that is pushing the boundaries of sustainable technology. It's incredibly rewarding to work alongside passionate students, tackling real-world challenges, and contributing to a project that not only promotes innovation but also fosters teamwork and leadership skills.”

Photos by Peter Means

If you want to have an impact on our students and faculty like those featured in this magazine, go here to support the College of Engineering. For more information, call (800) 533-1144.

-

Article Item

-

Article Item

-

Article Item