The fog harp's potential to deliver more clean water across the globe is threefold, but taking the product to market requires savvy industry partners.

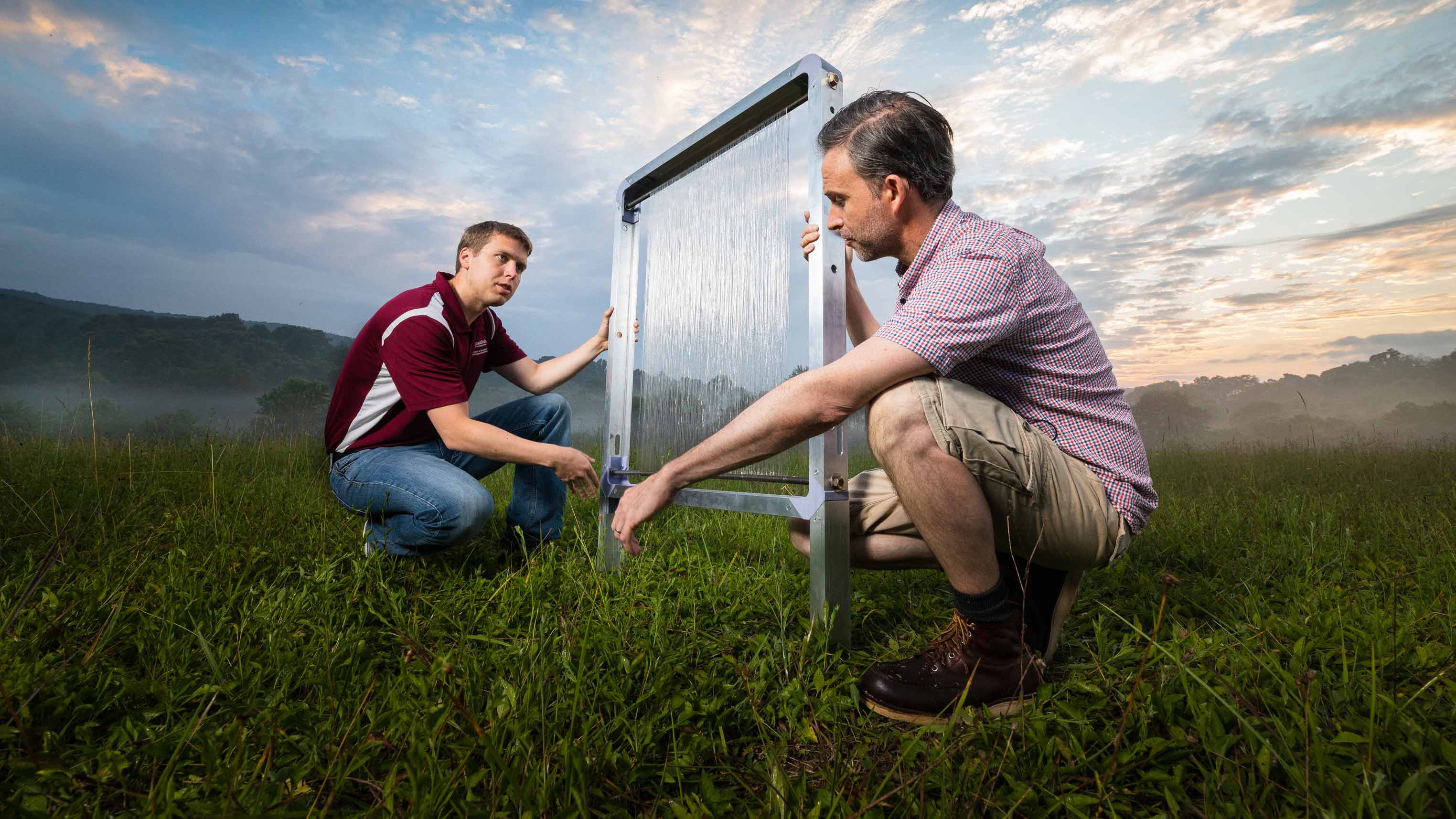

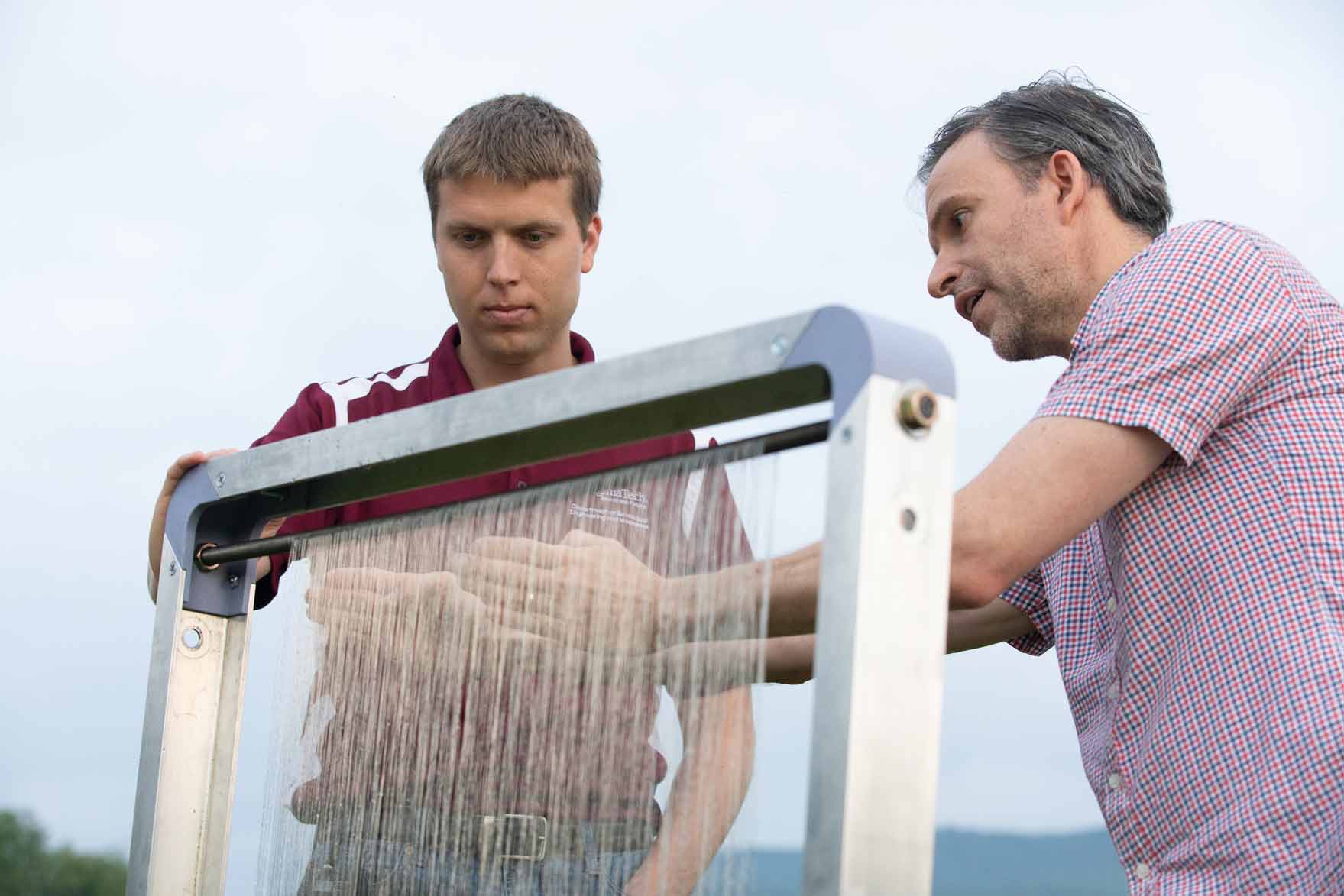

In the three months following the Virginia Tech fog harp’s public debut on March 28, 2018 Jonathan Boreyko and collaborator Brook Kennedy received almost 100 outside inquiries about the project. That’s roughly one email or phone call per day.

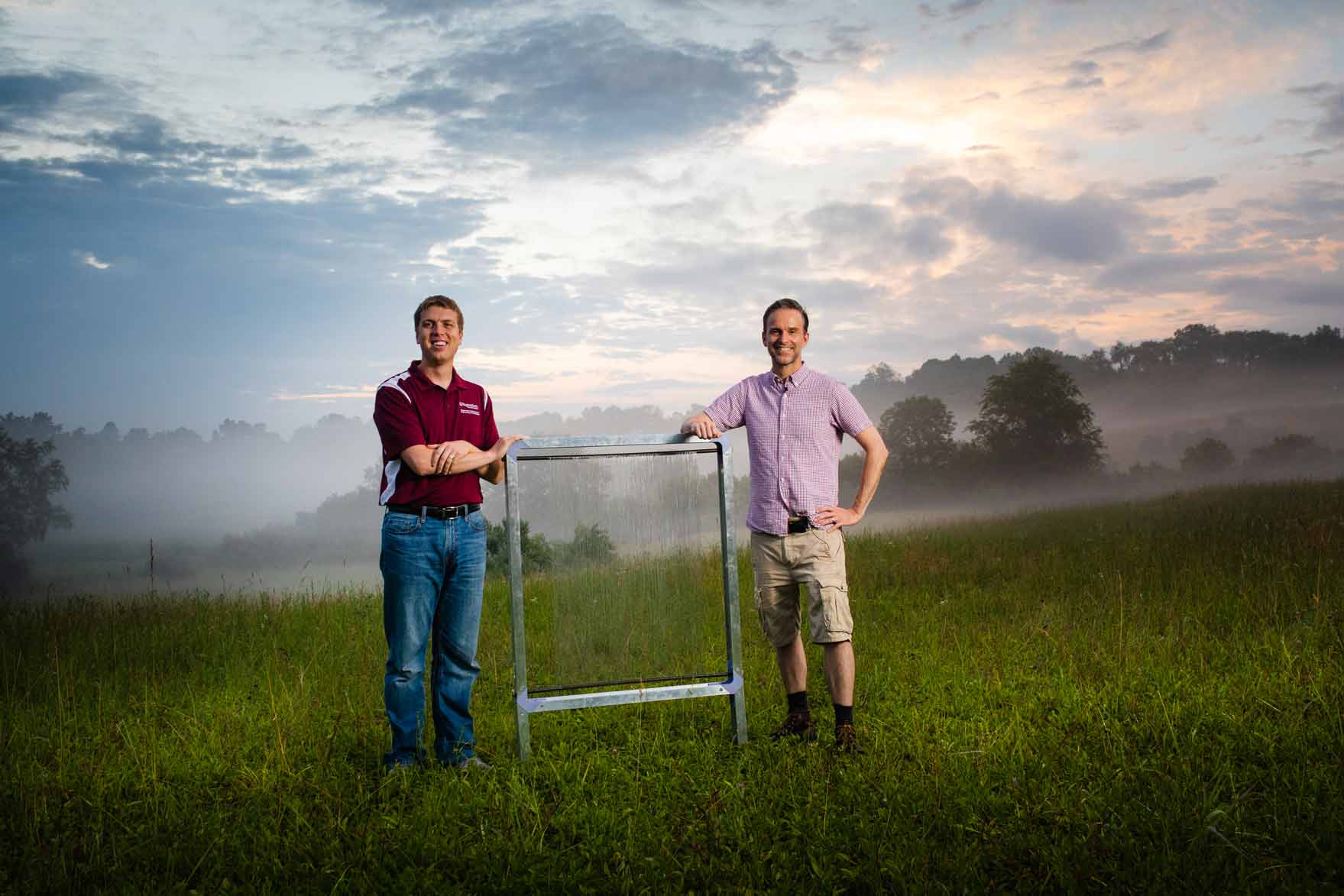

Boreyko, an assistant professor in the Department of Biomedical Engineering and Mechanics, was floored by the fog harp’s many fans. He and Kennedy, an associate professor in the Department of Industrial Design, heard everything from the practical to the fantastical.

A vineyard in Mexico wanted to know how to utilize the fog harp’s technology to quench the thirst of its grapes, while a nonprofit in Malaysia was interested in supplementing the flow of clean drinking water to local communities. An ambitious Russian scientist thought fog harps could be suspended from blimps in the air to power water turbines on the ground below.

The fog harp, it seemed, had struck an international chord. “I’ve just been amazed by the amount of interest we’ve had,” said Kennedy.

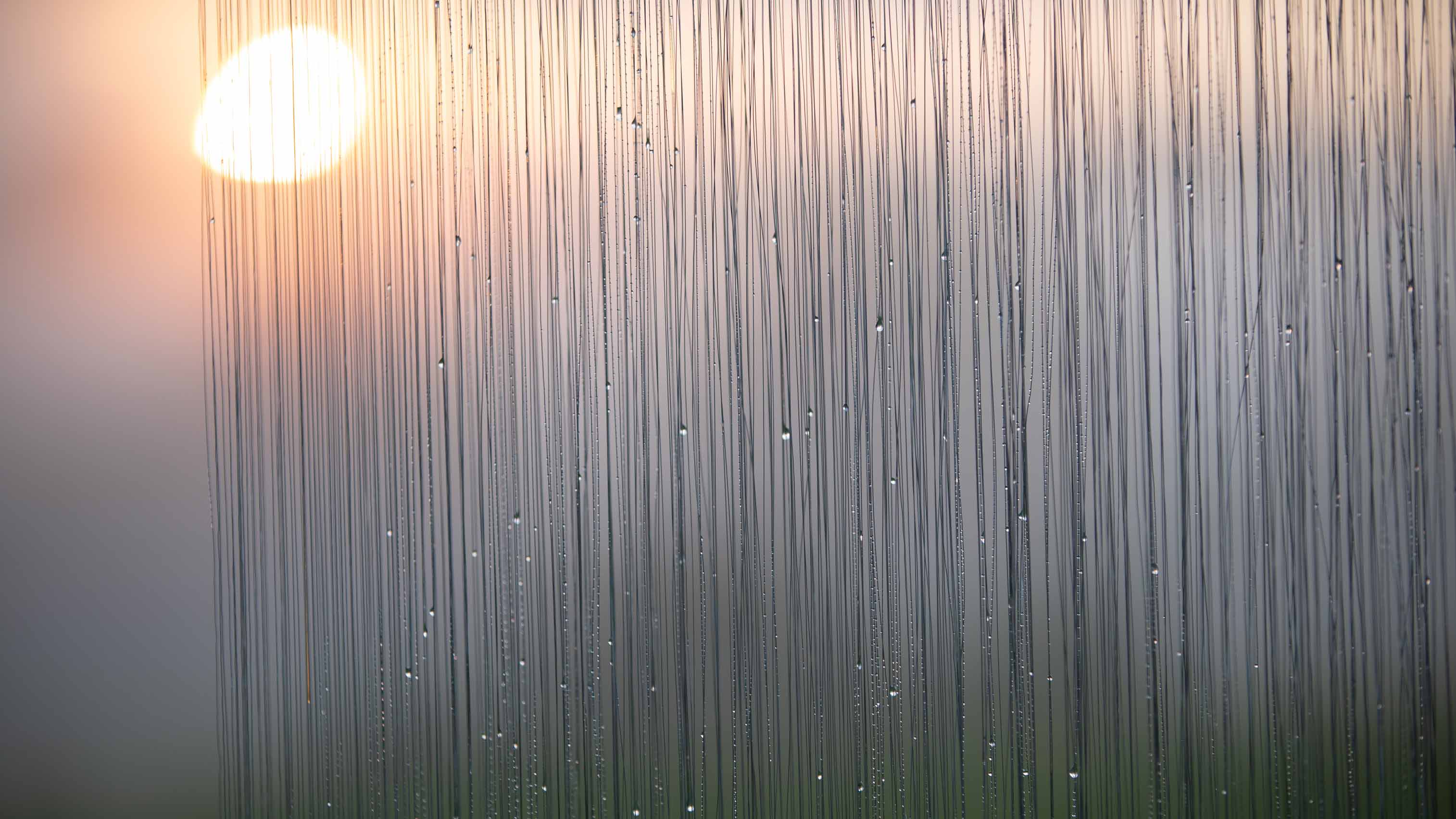

The invention is a novel combination of science and design, one that could potentially revolutionize the world’s approach to fog harvesting. A passive, durable, and effective method of water collection, fog harvesting uses nets to catch the microscopic droplets of water suspended in the wind that constitute fog.

As wind moves these water droplets through the nets, some get caught on the net's suspended wires. These droplets gather and merge until they have enough weight to travel down the nets and settle into collection troughs below.

While traditional fog harvesters use mesh netting to catch these droplets, the fog harp opts for a vertical array of wires instead, a design change that increases their collection capacity for clean water by threefold. That key discovery is what prompted the onslaught of attention from researchers, entrepreneurs, farmers, philanthropists, and citizen-scientists around the globe – not to mention investors.

Missed connections

That last category of interest began to intrigue the researchers. From the project’s inception, both had hoped to find a smoother, faster path through the fog harp’s stages of development and distribution. Often that meant finding an industry partner who might be interested in helping them build and refine an inexpensive, large-scale prototype to field test, or fund future iterations of the technology. Perhaps both.

But after several phone calls with potential investors, Boreyko and Kennedy started to accrue more questions about that process than they could answer on their own. Science was one thing, but screening investors? Asking tough questions about timelines and milestones? Filing patent applications and drafting licensing agreements?

“We thought a few of these processes just seemed really confusing and overly complicated,” said Boreyko. “Some of these emails we’d get from investors were impenetrable. As an academic, I was trained to conduct research and write papers for publication that summarize that research. But no one taught me how to file for a patent.”

Kennedy, who has worked professionally in industrial design and product development, also found these negotiations to be a bit daunting without a company behind him representing the team’s best interests.

“You’re trying to be smart and strategic with people who seem like they really want to help you, but you just don’t know,” said Kennedy. “How do you partner with external businesses from inside academia? And how do you deal smartly as a business person?”

Connecting with commercialization resources

Boreyko and Kennedy were encountering the complexities of technology commercialization first-hand. They had come up with a novel idea, designed a model, and tested it in the lab to verify results. But even though their invention had the potential to alleviate a very real and pressing problem (experts now predict that two-thirds of the world’s population won’t have access to enough clean water by the year 2025), they weren’t quite sure how to take the fog harp into the communities that needed it most.

“Moving technologies from the lab to market is critical,” said Boreyko. “But it’s not a core part of my job.”

And without the appropriate resources to navigate that process, the fog harp’s journey might have ended here – in the lab, on a shelf, or stuck somewhere inside a tangle of corporate legalese.

“But thankfully, Virginia Tech is really going in the right direction in terms of addressing that challenge,” said Boreyko. “The university recognizes that this is the hardest gap for faculty to cross. I’m glad we’re seeing more resources and services available in that area.”

One of those resources includes LINK, the university’s Center for Advancing Industry Partnerships, in collaboration with Virginia Tech Intellectual Properties. It was through these organizations that Boreyko and Kennedy first connected with Grant Brewer, associate director of technology commercialization, who not only helped the researchers vet potential investors, but also guided them through the provisional patent application process – the first step toward commercialization.

Why choose the route of commercialization? “Because as a university, we don’t make and sell products,” said Brewer.

If technology invented at Virginia Tech has the potential to change the world, commercialization is the fastest, most efficient way to make it happen. That’s where patents and industry partners come in, Brewer explained.

Often industry partners already have the facilities, resource infrastructure, and distribution networks in place to develop and mass produce a final product or field test a working prototype in a location prime for deployment. They offer pathways and expertise that universities can’t.

“But development is very expensive,” said Brewer. “So patents are a way for industry partners to protect their investment. In general, they protect opportunities for commercial endeavors.” Patents give companies a chance to recover the capital that gets spent on research and development, since products in the lab usually have a long way to go before they’re ready for the field.

“At the end of the day, patents provide important foundations – foundations that others can build on to serve the greater good. With commercialization partners, groundbreaking technologies like the fog harp have the potential to deliver significant global impact,” said Brewer.

Appreciating an objective evaluation

Just like a potential industry partner would, Brewer first evaluates new technology for its market potential and novelty, or patentability, to gauge commercial viability. In the case of the fog harp, the invention’s promise was clear from the start.

“I found that it was a pretty straight-forward and efficient approach to a problem in an existing field with a lot of possibility,” said Brewer. “I saw the novelty of the design and its performance improvements over existing solutions, and with it, the product potential.”

All of those emails sitting in Boreyko’s inbox didn’t hurt, either. The fact that the fog harp had garnered so much public attention in a short amount of time indicated that a market for the invention did indeed exist.

“Having someone who’s more business-minded on the team has been incredibly helpful,” said Kennedy. “Grant could ask those hard questions and push back on details. It’s nice to have that buffer between academia and the outside world.”

Boreyko also appreciated Brewer’s involvement as a buffer between short-term needs and long-term interests.

“What faculty need more than anything, at least in the short-term, is more funding for the research,” said Boreyko. “Sometimes that need for funding in today’s competitive academic climate can overshadow long-term strategies for licensing and partnerships. So having an unbiased third party here at Virginia Tech to help us bypass that potential conflict of interest has been really valuable.”

Finding the right partner

Thanks to collaborative efforts, the fog harp creators are currently in talks with a clean technology company that facilitates the more efficient use of natural resources. Although the

agreement hasn’t been finalized yet, both sides are optimistic about the fog harp’s potential to contribute to resolving water scarcity challenges across a multitude of scales – from individual households to commercial as well as industrial applications.

Finding a good fit for the fog harp was important, said Boreyko and Kennedy, and they feel they’ve connected with the right partner.

Over the next several years, the company will help the team optimize the manufacturability, durability, and overall performance of the fog harp. The first full-scale tests are set to take place at Virginia Tech’s Kentland Farm and in the future the researchers hope to conduct field tests in a decentralized international location.

The pending partnership not only moves the fog harp closer to communities around the world, but Boreyko and Kennedy say it’s also important for another reason: It has confirmed their approach to research with a cross-disciplinary, real-world focus.

“I don’t think it’s a coincidence that the fog harp is a collaboration across disciplines and that it has attracted an industry partner so quickly,” said Boreyko. “From the beginning, this project wasn’t just about ‘Look what we can do.’ We were interested in making a discovery that was actually amenable to real-life implementation. The more we can cross-collaborate, the more we can close those gaps in translation more effectively.”

Kennedy agreed. “I know a lot of people talk about collaboration, but that concept wasn't just lip service for us. This was pure and wonderful science that had its eye on real-world application."

This project was initially funded in part by the Virginia Tech Institute for Creativity, Arts, and Technology.

Photos by Peter Means, video by Jack Beach.

If you want to have an impact on our students and faculty like those featured in this magazine, go here to support the College of Engineering. For more information, call (540) 231-3628.