Before mechanical engineer Amy Elliott landed at Oak Ridge National Laboratory, she helped spearhead the additive manufacturing charge at Virginia Tech – and almost won a reality TV show. Learn more about her journey in this Q&A.

By Alex Parrish, with Amy Elliott

Amy Elliott was a Ph.D. student in the Department of Mechanical Engineering from 2009 until her dissertation defense in 2013, and she arrived on campus during a very unique time. As she began her studies, the boom of additive manufacturing, also known as 3D printing, was just getting started.

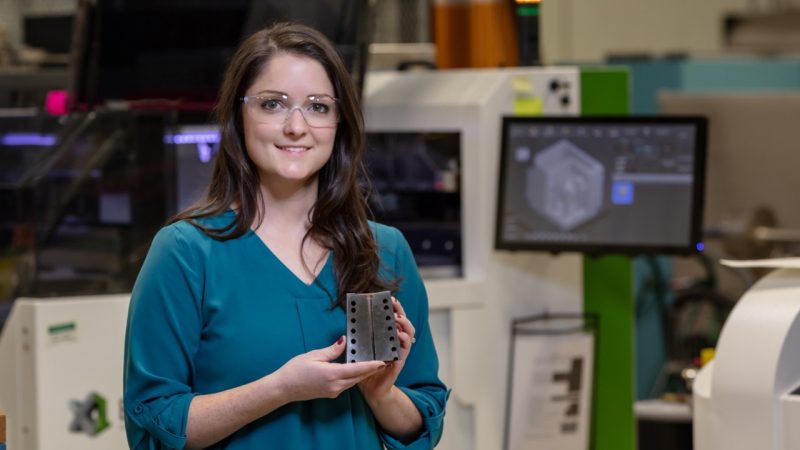

During her time as a student, Elliott worked with campus 3D printing pioneer and L.S. Randolph Professor Chris Williams in the Design, Research, and Education for Additive Manufacturing Systems (DREAMS) Lab to build some of the earliest applications for the technology. She finished her degree at Virginia Tech and joined Oak Ridge National Lab in 2013, where today she leads the Robotics and Intelligent Systems group.

2013 was also the year that brought Elliott some celebrity status, as she was chosen for the cast of “The Big Brain Theory,” a reality television show on the Discovery Channel that brought young engineers and scientists together to find creative approaches to solving some pretty outrageous problems. The show was also a competition, and Elliott finished second out of ten contestants. Since 2015, she has also been a regular contributor on “Outrageous Acts of Science,” which airs on the Science Channel and deconstructs the physics of fun, homemade engineering projects often seen on social media videos.

In March of this year, she appeared as a 3D-printed statue at the Smithsonian as part of the museum’s “#IfThenSheCan” exhibit, coinciding with Women’s History Month and featuring 120 women in STEM fields. She holds 4 patents and has over 15 patent applications pending with the U.S. Patent and Trademark Office.

On coming to Virginia Tech

Q: Can you talk about your journey coming from your master’s degree at Tennessee Tech to your doctoral work at Virginia Tech?

A: I had some buddies from the Baja Team at Tennessee Tech who had been to Virginia Tech, and they invited me along to a graduate visit weekend. Really, I owe it to those guys for lining me up with Virginia Tech. I bummed a ride with my friend, then I stayed with another friend. I met with Chris Williams, my Ph.D. advisor, and I thought he was the coolest guy ever. I wasn’t exactly sure what the project was, but I knew it was going to be fun, so I was super excited.

Q: Do you remember the first thing you ever 3D printed?

A: I chose a dragon, and I found the file online. I used this million-dollar machine to print a dragon as a demo piece. I think he [Williams] wanted me to print something a little more serious. In the end, it got a lot of attention. Everybody wanted to see the dragon.

Q: How did your time at Virginia Tech prepare you for a role at a national lab?

A: I feel like the DREAMS Lab and my different courses and professors exposed me to a lot of ideas and concepts, as well as different aspects of my field that made me feel really well-rounded when I started in industry. I got to work with interdisciplinary research. I got to work with the polymer people, and they were really nice to let me do characterization on their equipment. I got to work with the physics people, work on their equipment, and do some research with them. The diversity of technology and expertise at Virginia Tech really served me well.

On innovation and leadership

Q: If you could engineer a lab to function optimally, what would that look like?

A: The engineers’ desks or offices are on the same floor as the shop, so every time they leave their desk, they're looking at projects that are happening. It sounds stupid that location matters so much, but it does. If you’re in the same space as your project, your brain is working while you’re not thinking about it.

Q: Has anything you’ve made wound up in something people would recognize?

A: There is this problem with desktop 3D printing where you want your part to stick on the build plate, but you don’t want it to stick so hard that you can’t get it off without ripping the whole machine apart. I have a patent for a cleated build platform. There’s a company that’s actually using it. It was exciting to get to that point here at Oak Ridge, and exciting to see people use it. It’s for large industrial printers.

Q: In your 2013 TED talk, you said, “A true artist is always a part of the creation process.” Do you consider yourself an artist?

A: I think all engineers want to aspire to be something like an artist. There are a lot of similarities between art, engineering, and science. When you’re creating a thing, you have to do a lot of thinking about it and sketching. The point of the TED talk was that just like an artist is right there making this piece of art, remixing and correcting, you as an engineer need to be there right in the middle, too. Disconnecting assembly and building from the design, you’re missing a huge opportunity. Being there in the build, touching and feeling and looking and assembling, you gain an intuition you can’t get on a computer. Then you use that intuition to make the next version so much better.

Q: There was a moment in “The Big Brain Theory” where you felt like your idea was worth hearing, but you weren’t heard. How has that moment influenced you as a leader?

A: It’s so important to make sure that your team feels involved, that you have their buy-in, and that they’re being listened to. I always want whoever is working with me to feel like they have ownership. They have a piece of this. I want to hear what you think. Asking for someone else’s thoughts is free; it doesn’t cost you anything except a couple of minutes. Every time I’ve done that, it’s been rewarding. When you get other people involved and they feel a part of the project, your results are going to be so much better. If you can get the team to believe in it, if you have a team of people who believe in your mission, you can do anything.

On mentorship, support, and opportunity

Q: What’s a piece of great advice that you were given?

A: “The guys aren’t holding their gender on their shoulders, and neither should you.” That was advice from my Ph.D. advisor, Chris Williams. A week before I was supposed to go film the “Big Brain Theory,” I sat down in Chris’s office and I said, “I’m not going. I’m going to make all female engineers look stupid, and I don’t want to go.” He said, “Okay. The guys aren’t holding their gender on their shoulders, and neither should you.” Really, I owe it to him that I even went on that show. Maybe guys think about that, but when you’re a minority, you kind of feel like you’re representing that minority. There’s that little extra bit of pressure to excel. My advice to the ladies is that I don’t think the guys feel that way, so leave that at the door.

Q: Do you think women are seeing increased opportunities in engineering, and do you think those are good opportunities?

A: I think that the field is right for women. Not every place is equal. At least for me, I’ve always worked in government-related work, and that’s been a supportive atmosphere for me as a woman. Private industries might have some catching up to do, and maybe it’s not perfect, but there are amazing opportunities out there. What I like to tell young women is, “These are great career options, and they pay very well. The people you work with are amazing. Typically, engineers and scientists, we’re just focused on the solution. There’s very little drama.”

Q: Who are some female mentors who have played a role in making you who you are?

A: On my high school robotics team, there were teachers who were supportive and mentored me. At Virginia Tech, Mary Kasarda was a great role model. I had never really seen a female have a discussion about technical content before, and the way she answered questions helped me find a way that worked for me.

On current projects and looking ahead

Q: When you found out you were going to have a statue at the Smithsonian, how did that feel?

A: I didn’t realize how big of a deal it was until all the pictures and everything had happened. Realizing the reach and how many people saw it was the coolest part. We got scanned for them a couple years ago. We were invited to this AAAS [American Association for the Advancement of Science] ambassadorship conference, and we thought it would be social media coaching and networking. Turns out, it’s like Oprah. “We’re going to 3D scan you and turn you into a statue!” The whole ambassadorship has been an amazing experience.

Q: Did you do an outreach project as part of your AAAS ambassadorship?

A: Yes! My project was to write and illustrate a book called, “Where Does Electricity Come From?” It’s a kid’s book. One of the things that I found working at the Department of Energy is that most people, maybe eight out of 10 or less, don’t know where electricity comes from. It’s not their fault; we don’t talk about that enough in K-12. This book sets that groundwork. Along the way, this cute character named Amelia Gearheart introduces all of her friends who work in STEM and trades: Maya the Machinist, Wendy the Welder, Keisha the Chemical Engineer, Mindy the Miner. When you flip to the back of the book, it has pictures of actual ambassadors, STEM role models, next to the characters for real-life examples. I’m still working with my publisher to get it out.

Q: What do you see as the next big thing on your horizon?

A: Professionally, I want to keep innovating. I love the course I’m on, being able to work on so many different projects. I’d like to be a part of the leadership here [at Oak Ridge] at some point. I really enjoy where I am, and getting to invent things and work on hard problems and come up with fun solutions.

Photos courtesy Amy Elliot

If you want to have an impact on our students and faculty like those featured in this magazine, go here to support the College of Engineering. For more information, call (540) 231-3628.